We Have Strong Technical Support

Technical Write-up

SOLAR Modules

Technical Advancement of Trina PV Modules

Trina solar is a global leading provider for PV module and smart energy solution, Trina Solar delivers PV products, applications and services to promote global sustainable development.

Trina solar PV modules are widely used in every installation across world-wide because of its aesthetical looks and excellent performance.

The Trina PV modules is available from 360W to 670W under various model name Vertex, Vertex S, Tallmax, Honey and Duomax twin.

Earlier Generations - Trina PV Modules:

In the earlier generation models, the maximum possible PV module was <400wP, 72cells. So, for a 1kW system, we required 3PV modules considering 330wP as ideal case.

However, now we need just 2 PV modules to power up a 1kW system. This is because of currently available 500wP modules. The PV Modules are getting advanced every day.

We can say the main contribution to this development is because of the global PV module manufacturer and the growing solar industry essentials.

Trina Solar is one of the primary contributors to this PV module advanced technology development.

Trina Solar has launched their new product PV Module under VERTEX models, ranging from 500wP to 670wP.

How Trina solar and other PV module manufacturer able to manufacture a single 670wP PV module with the same PV area dimension. How are they achieving high wattage with single PV module?

Let us take a closer look into the developments that made this possible.

The earlier generation model PV Module were made of 60 and 72 cells depending upon the required capacity. But these cells are single full cell.

Cell Cutting Technology – Trina PV Modules

Today’s generation PV Modules comes with 110, 120 and 144 cells depending upon the capacity of PV module. But the PV modules size are not much different compared with earlier models.

These are known as cell cutting technology. In cell cutting technology the PV module manufacturer will split the cell. If the cell is split into half it is known as Half cell technology. If it is into 1/3 of cell it is a 1/3 split cell technology.

Vertex Models – Trina PV Modules

The Vertex S, model involves a half-cut cell technology. In half cut cell technology, the cells are cut using laser technology. Cutting the cell into half reduces the loss that occur in current flow from one cell to another within an entire module. Thereby reducing the resistance loss on entire module and boosting the efficiency.

The newer Vertex models comes with 1/3 cut cell technology. Here the cell is cut into 1/3rd and hence the resistance between the cells in a module is reduced and increased efficiency up to 21% is made possible.

The 500W+ Vertex module employs cells based on 210mm Silicon wafers to bring the highest power output with reduced module size.

Trina Vertex modules are low voltage and high current design modules. The reason behind this design is that basically a PV system requires maximum output power and reduced BOS cost.

The power formula for DC System is P=VI, where V voltage and I current. The power output is going to be the same if anyone of the voltage/ current increases.

Thus, by maintaining a low voltage design on PV modules, the installer can accommodate a greater number of PV modules in a single string BOS cost for DC cable is reduced and high power is achieved at same time.

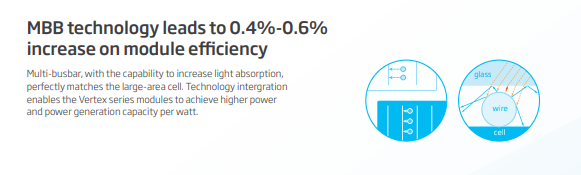

MBB Technology – Trina PV Modules

Trina Modules to further achieve a greater efficiency, the PV modules are coming with Multi Bus Bar Technology. The cells inside a module are interconnected with high density interconnect multi bus bars. With this technology, light absorption is high and large area of the cell further enables to achieve high power and power generation by Watt.

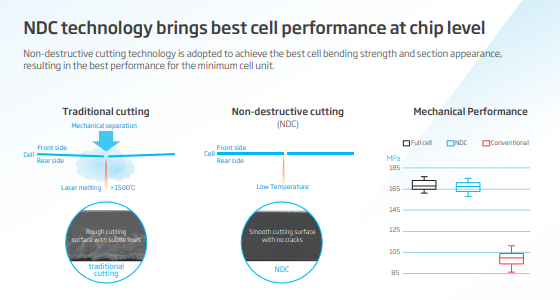

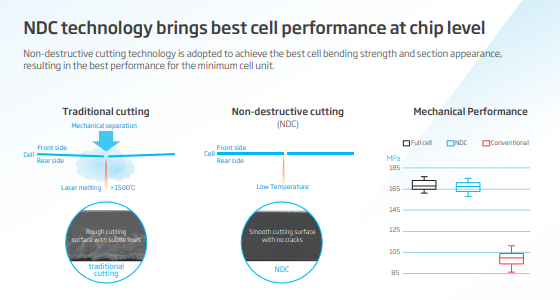

NDC Technology – Trina PV Modules

This cell cutting technology in Trina PV modules are performed in a unique method knows as NDC (Non- Destructive Cutting) technology.

NDC in compared to traditional cutting tech, low temperature is applied to split the cell without damaging it. Mostly the temperature is <130 degrees to split the cell.

This is a thermal laser separation technology so no mechanical pressure applied over cells, provides smooth surface with no crack. The NDC provides breakage free cell. The breakage rate is <0.02%. Thus, boosting the cell performance and helps achieve high power in watts.

High Density Interconnection Technology – Trina PV Modules

Trina PV modules, further manages to achieve higher power output per module with less size and more power by interconnecting the cells in a module close to each other cell. This is done by flattening the cell connection area. In a traditional PV module, we can see a small gap between cells and are interconnected with some welding tapes. Trina is relieving this out with the use of flattened welding tape to reduce the cell gap to 0.2~0.5mm. So, a greater number of cells can fit in the same panel with same size, risks due to micro cracks are less and increased yield output.

Conclusion

To conclude, less size and more output of each module considering the residential and commercial requirements, is the motive behind Trina Advancement over their PV modules.

In the past we needed 3 PV modules to power up a 1kW system but in upcoming future with all the PV modules development we may only need 1 or 2 PV modules to power up the same 1kW system.